Umatshini wokugrumba we-CNC we-S8F Frame Double Spindle

| Igama lepharamitha | Iyunithi | Ixabiso lepharamitha | ||

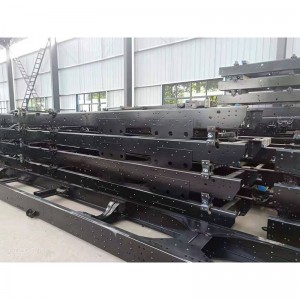

| Iiparamitha zenkqubo yesakhelo | Izinto eziphathekayo | Intsimbi eqengqelekayo eshushu eyi-16MnL | ||

| Amandla amakhulu okuxinana | I-MPa | 1000 | ||

| Unikeze Amandla | I-MPa | 700 | ||

| Ubukhulu obukhulu bokubhola | mm | 40(IsiNgesi)Ibhodi eneeleya ezininzi) | ||

| Ukucubungula i-stroke | i-axis | mm | 1600 | |

| I-axis ka-Y | mm | 1200 | ||

| Ukubambelela ecaleni kweselula | i-axis | mm | 500 | |

| I-Xaxis | mm | 500 | ||

| I-spindle yokubhola | ubungakanani | isiqwenga | 2 | |

| I-spindle taper | BT40 | |||

| Uluhlu lobubanzi bokubhola | mm | φ8~φ30 | ||

| Umgama omncinci wokubhola weentloko zamandla amabini ngaxeshanye | mm | 295 | ||

| I-Stroke yokutyisa | mm | 450 | ||

| Isantya esijikelezayo | r/min | 50~2000(IsiNgesi)I-Servo engenamagxa) | ||

| Izinga lokutya | mm/umzuzu | 0~8300 (iServo engenasinyathelo) | ||

| Amandla enjini ye-servo ye-Spindle | kW | 2×7.5 | ||

| I-torque elinganiswe nge-Spindle | Nm | 150 | ||

| I-torque ye-spindle | Nm | 200 | ||

| Amandla aphezulu okutya okuphotha | N | 7500 | ||

| Imagazini yezixhobo | Ubungakanani | isiqwenga | 2 | |

| Ifomu yesiphatho | BT40 (Nge-drill eqhelekileyo ye-taper shank twist) | |||

| Ubungakanani besixhobo semagazini | isiqwenga | 2×4 | ||

| Inkqubo ye-CNC | Cindlela yokulawula | Inkqubo ye-Siemens 840D SL CNC | ||

| Inani lee-axes ze-CNC | isiqwenga | 7+2 | ||

| Amandla emoto yeServo | I-Xaxis | kW | 4.3 | |

| I-axis ka-Y | 2x3.1 | |||

| I-axis ka-Z | 2x1.5 | |||

| I-Xaxis | 1.1 | |||

| I-Xaxis | 1.1 | |||

| Inkqubo ye-hydraulic | Uxinzelelo lokusebenza kwenkqubo | I-MPa | 2~7 | |

| inkqubo yokupholisa | Cindlela yokufunxa | Indlela yokupholisa i-Aerosol | ||

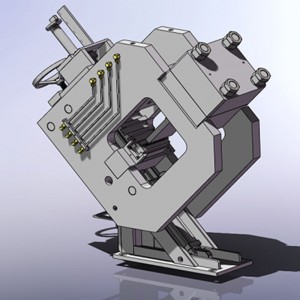

1. Umatshini oyintloko uquka ikakhulu ibhedi, i-gantry ehambayo, intloko yamandla okubhola (2) (yokubhola i-steel twist drill drill ekhawulezayo), indlela yokutshintsha izixhobo (2), indlela yokubeka, ukubopha kunye nokufumanisa, kunye netroli yokutya (2 A), inkqubo yokupholisa ephucukileyo, inkqubo ye-hydraulic, inkqubo ye-CNC, isigqubuthelo sokukhusela kunye nezinye iindawo.

2. Umatshini usebenzisa uhlobo lwebhedi esisigxina kunye ne-gantry eshukumayo.

3. I-axis Y ethe tye kunye ne-axis Z ethe nkqo yeentloko ezimbini zamandla okubhola zihamba ngokuzimeleyo. Intshukumo ye-axis Y yentloko nganye yamandla iqhutywa sisikrufu esahlukileyo, esinokunqumla umgca osembindini wezinto; i-axis nganye ye-CNC ikhokelwa sisikhokelo sokuqengqeleka esithe tyaba. I-AC servo motor + i-ball screw drive. Intloko yamandla inoyilo oluchasene nokungqubana ukuthintela intloko yamandla ekungqubaneni ngexesha lokusebenza ngokuzenzekelayo.

4. Intloko yamandla okubhola isebenzisa i-spindle echanekileyo engeniswe ngaphakathi kwiziko lokugaya; ixhotyiswe ngomngxuma we-BT40 taper, kulula ukutshintsha isixhobo kwaye ingabotshelelwa kwiidrill ezahlukeneyo; i-spindle iqhutywa yi-servo spindle motor, enokuhlangabezana neemfuno zesantya esahlukeneyo kunye nemisebenzi yokutshintsha izixhobo.

5. Ukuze kuhlangatyezwane nokucutshungulwa kweendawo ezahlukeneyo zokuvula, umatshini uxhotyiswe ngeemagazini zezixhobo ezikwi-intanethi (2), kwaye iintloko ezimbini zamandla zinokutshintsha ngokuzenzekelayo izixhobo.

6. Lo matshini unesixhobo sokubona ngokuzenzekelayo esizimeleyo, esinokubona ngokuzenzekelayo ububanzi bezinto kwaye sibuyisele kwinkqubo ye-CNC.

7. Icala ngalinye lebhedi yomatshini lixhotyiswe ngeseti yokulungelelaniswa kwelaser ukuze ifreyimu ibekwe ngendlela erhabaxa.

9. Lo matshini uxhotyiswe ngenkqubo ye-hydraulic, esetyenziswa kakhulu ekubekeni nasekubambeni izinto.

10. Lo matshini uxhotyiswe ngenkqubo yokupholisa ye-aerosol yokugrumba nokupholisa izinto.

11. Umqadi we-gantry yomatshini uxhotyiswe ngesigqubuthelo sokukhusela esifana ne-organ, kwaye umqolo webhedi uxhotyiswe ngesigqubuthelo sokukhusela esifana nepleyiti yentsimbi ye-telescopic.

12. Umatshini usebenzisa inkqubo yolawulo lwamanani ye-Siemens 840D SL, enokwenza ucwangciso lwe-CAD oluzenzekelayo kwaye inomsebenzi wokuqaphela umaleko. Inkqubo inokumisela ngokuzenzekelayo umgama wokusebenza ngokobude besixhobo (ukufakwa ngesandla) kunye nokuphakama kwesakhelo, ngokubanzi yi-5mm, kwaye ixabiso layo linokubekwa ngokweemfuno.

13. Umatshini uxhotyiswe ngenkqubo yokuskena yebha ethe tye (ikhowudi yebha enemilinganiselo enye, umgangatho wokubhala ikhowudi weCODE-128), ebiza ngokuzenzekelayo inkqubo yokucubungula ngokuskena ikhowudi yebha ethe tye yesakhelo ngesikena esiphathwayo esingenazingcingo.

14. Lo matshini unomsebenzi wokubala wokuqokelela ngokuzenzekelayo inani lemingxuma yokugrumba kunye nenani lezinto ezicutshungulweyo, kwaye awunakususwa; ukongeza, unomsebenzi wokubala imveliso, onokurekhoda inani lezinto ezicutshungulweyo yinkqubo nganye yokucubungula, kwaye unokubuzwa kwaye ususwe.

| HAYI. | Into | uphawu | Imvelaphi |

| 1 | Izikhokelo eziLula | I-HIWIN/PMI | ITaiwan, iTshayina |

| 2 | I-spindle echanekileyo | UKenturn | ITaiwan, iTshayina |

| 3 | Inkqubo yokuskena ibhakhowudi ethe tyaba | ISIMBO | IMelika |

| 4 | Inkqubo ye-CNC | I-Siemens 840D SL | Jemani |

| 5 | Simoto ye-ervo | I-Siemens | Jemani |

| 6 | Injini ye-servo ye-Spindle | I-Siemens | Jemani |

| 7 | Iindawo eziphambili ze-hydraulic | I-ATOS | ElamaTaliyane |

| 8 | Itsheyini yokurhuqa | IsiMisumi | Jemani |

| 9 | Izixhobo zombane eziphantsi kwamandla ombane | USchneider | Fransi |

| 10 | Amandla | I-Siemens | Jemani |

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba