Umgca weMveliso eDibeneyo ye-RDS13 CNC Rail Saw and Drill

| Into | ipharamitha | Inkcazo |

| Imodeli yesitimela esisiseko | Uhlobo lwezinto | 50Kg/m,60 kg/m,75 kg/m ubunzima 340~400HB |

| Isitimela esiphambili sentsimbi ye-alloy, i-insert yentsimbi ye-alloy, ubunzima obuyi-38 HRC~45 HRC | ||

| Ubungakanani besitimela | Ubude bezinto eziluhlaza | 2000~1250mm |

| Iimfuno zokucubungula | Izinto eziphathekayoubude | 1300~800mm |

| Izinto eziphathekayoukunyamezela ubude | ±1mm | |

| Ubuso bokuphela bume nkqo | <0.5mm | |

| Ububanzi bokubhola | φ31~i-φ60mm | |

| Ububanzi bomngxumaukunyamezelana | 0~0.5mm | |

| Uluhlu lokuphakama komngxuma | 60~100mm | |

| Iiparameter eziphambili zobugcisa bomatshini | Indlela yokusarha | Isarha esijikelezayo (isantya esiphezulu) |

| Amandla enjini ye-spindle | 37kW | |

| Ububanzi beblade yesarha | Φ660mm | |

| Isantya esiphezulu sokuhamba se-X axis | 25m/ngomzuzu | |

| Isantya esiphezulu sokuhamba se-axis Z | 6m/ngomzuzu | |

| Uhlobo lokuphotha lokomba | BT50 | |

| UkubholaIsantya se-spindle | 3000r/ngomzuzu | |

| UkubholaAmandla enjini ye-servo ye-Spindle | 37kW | |

| Isantya esiphezulu sokuhamba se-axis ye-X, Y, Z | 12m/ngomzuzu | |

| Uhlobo lwe-chamfering spindle | NT40 | |

| I-chamfering spindle RPM Max. | 1000 | |

| Amandla enjini ye-Chamfering spindle | 2.2 kW | |

| Isantya sokuhamba kwe-axis ye-Y2 kunye ne-axis ye-Z2 | 10m/ngomzuzu | |

| I-chuck yemagnethi esisigxina yombane | 250×200×140mm(enye200×200×140mm) | |

| Ukufunxa emsebenzini | ≥250N/cm² | |

| Inkqubo yokususa iitships | 2iseti | |

| Uhlobo lokuhambisa itshiphusi | Itsheyini ethe tyaba | |

| Isantya sokususa iitships | 2m/ngomzuzu | |

| Inkqubo ye-CNC | I-Siemens828D | |

| Inani leenkqubo ze-CNC | Iseti ezi-2 | |

| Inani lee-axes ze-CNC | I-axis eyi-6+1,I-axis eyi-2+1 | |

| Ukuphakama kwetafile yokusebenza | 700mm | |

| Ukuphakama kwetafile yokusebenza | malunga ne-37.8m×8m×3.4m |

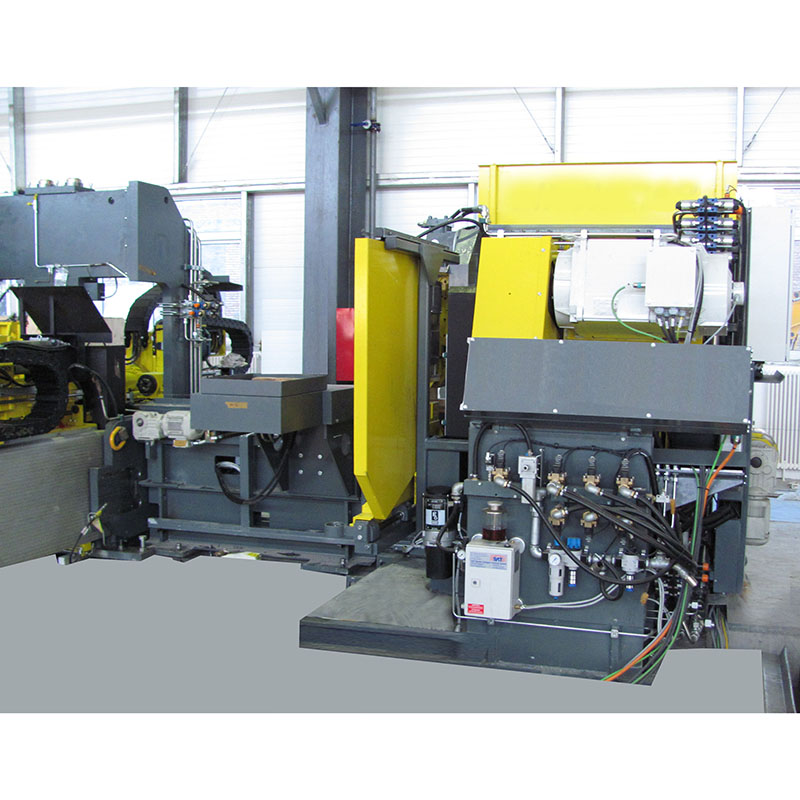

1. Kukho isixhobo sokususa itshiphusi yeblade yesarha kwiyunithi yokusarha, esinoxanduva lokususa uthuli lwesarha kwiblade yesarha. Isixhobo sokupholisa nesokuthambisa siyathambisa kwaye sipholise indawo yokusarha, nto leyo ephucula ubomi benkonzo yeblade yesarha. Iireyili zesikhokelo, kwaye ikholamu eshukumayo ifakwe kwibhedi yomatshini.

2. Inkqubo yokubhala iikhowudi

Inkqubo yokufaka iikhowudi ifakwe kwicala langaphandle le-power head ram, kwaye ixhotyiswe ngekhompyutha ephetheyo ukuze icwangcise kwaye ilawule inkqubo yokufaka iikhowudi.

3. Iyunithi yokugrumba

Ulwakhiwo lwekholamu luyamkelwa, kwaye ikholamu isebenzisa isakhiwo esidityanisiweyo sepleyiti yentsimbi. Emva konyango lokufakelwa kunye nokuguga okwenziweyo, uzinzo lokuchaneka kokucubungula luyaqinisekiswa.

4. Intloko yokubhola

Intloko yokubhola yenziwe ngohlobo lwe-ram enobulukhuni obuqinileyo. Ibhanti yexesha inamandla aphezulu okutsalwa, ihlala ixesha elide, ingxolo ephantsi kunye nokungcangcazela okuphantsi xa isebenza ngesantya esiphezulu. I-spindle echanekileyo ipholile ngaphakathi kwaye ingenanto, kwaye ixhotyiswe nge-45° four-petal claw broach mechanism. Isiphelo esingasemva se-spindle echanekileyo sixhotyiswe nge-hydraulic punching cylinder ukuze kube lula ukutshintsha izixhobo.

5. Ibhentshi yokusebenzela

Ibhentshi yokusebenzela yamkela isakhiwo sokuwelda ipleyiti yentsimbi, unyango lwangaphambi kokwenziwa ngaphambi kokuwelda, kwaye emva kokuwelda, uncedo loxinzelelo kunye nonyango lokuguga kobushushu lwenziwa ukuqinisekisa ukuchaneka kunye nozinzo.

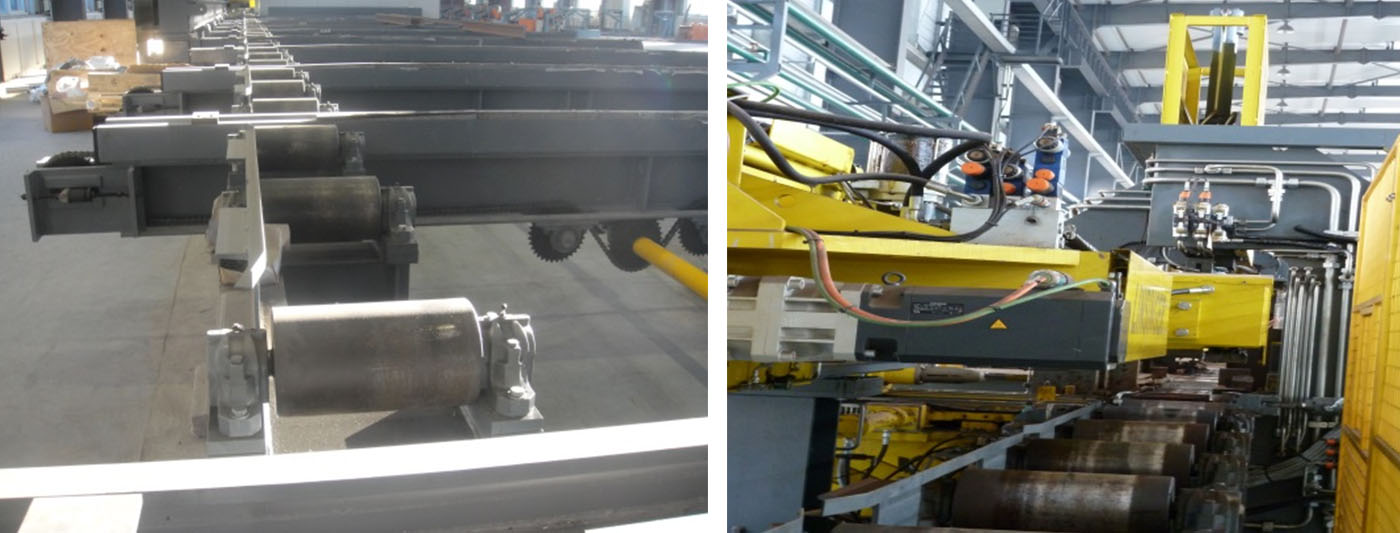

6. Inkqubo yokususa iitships

I-automatic chip conveyor luhlobo lwetyathanga elithe tyaba, elineeseti ezimbini zizonke. Iseti enye isetyenziselwa iyunithi yokusarha kwaye ibekwa phantsi kwecala le-saw blade. Enye iseti isetyenziselwa iyunithi yokubhola, ebekwa phakathi kwebhedi kunye nebhentshi yokusebenzela. Iifayile zentsimbi ziwela kwi-chip conveyor ngesikhokelo se-chip kwibhentshi yokusebenzela, kwaye iifayile zentsimbi zithuthwa ziye kwibhokisi yokufaka iifayile zentsimbi entloko nge-chip conveyor.

7. Inkqubo yokuthambisa

Kukho iiseti ezimbini zeenkqubo zokuthambisa ezizenzekelayo ezisetyenziswa ngokuzenzekelayo, enye yeyokusarha kwaye enye yeyokugrumba. Inkqubo yokuthambisa ezenzekelayo yenza ukuthambisa okungenaziphazamiso kwisibini esikhokelayo esijikelezayo, isibini sesikrufu sebhola, kunye nesibini se-rack kunye ne-pinion ukuqinisekisa ukuchaneka kwazo kunye nobomi benkonzo.

8. Inkqubo yombane

Inkqubo yombane isebenzisa inkqubo yolawulo lwamanani ye-Siemens 828D, iiseti ezimbini zizonke, iseti enye isetyenziselwa ukulawula iyunithi yokusarha, irakhi yokutya ethe tye, itafile yerola yokutya kunye netafile yerola ephakathi. Enye iseti isetyenziselwa ukulawula iyunithi yokugrumba, ibhentshi yokusebenzela 1, irakhi yokukhulula impahla ethe tye kunye nebhentshi yokusebenzela.

| HAYI. | Into | Uphawu | Imvelaphi |

| 1 | Isibini sesikhokelo esinomgca | HIWIN | ITaiwan, iTshayina |

| 2 | Inkqubo ye-CNC 828D | I-Siemens | Jemani |

| 3 | Simoto ye-ervo | I-Siemens | Jemani |

| 4 | Inkqubo yokubhala iikhowudi | Iphrinta ye-LDMinkjet | IShanghai, eTshayina |

| 5 | Impompo yeoyile yeHydraulic | I-Justmark | ITaiwan, iTshayina |

| 6 | Itsheyini yokurhuqa | I-CPS | Khoriya eseMzantsi |

| 7 | Iigiya, iirakhi | I-APEX | ITaiwan, iTshayina |

| 8 | Isinciphisi esichanekileyo | I-APEX | ITaiwan, iTshayina |

| 9 | I-spindle echanekileyo | UKENTURN | ITaiwan, iTshayina |

| 10 | Izinto eziphambili zombane | USchneider | Fransi |

Qaphela: Lo ungentla ngumthengisi wethu oqhelekileyo. Ingatshintshwa zizinto ezifanayo ezisemgangathweni zolunye uphawu ukuba umthengisi ongentla akanakukwazi ukubonelela ngezixhobo xa kukho into ekhethekileyo.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba