Umatshini wokubhola we-RDL25A CNC weeRails

| Inkcazo yesitimela esicutshungulweyo | Uhlobo lwesitimela | 43Kg/m,50Kg/m,60Kg/m,75Kg/m,I-UIC54,I-UIC60 |

| ATimodeli kaloliwe | 50AT,60 AT,I-UIC60D40 | |

| Ireyile yamaphiko ecandelo elikhethekileyo | 60TY | |

| Uluhlu lobungakanani besitimela | Ububanzi obusezantsi | 114-152mm |

| Ukuphakama kwesitimela | 128-192mm | |

| Iwebhuubukhulu | 14.5-44mm | |

| Ubude besitimela (emva kokusarha) | 6-25m | |

| Uhlobo lwezinto zikaloliwe | U71Mn σb≥90Kg/mm² HB250PD3 σb≥98Kg/mm² HB290-310 | |

| Ukubholaintloko | Ububanzi | φ20~φ33 |

| Uluhlu lobude | 3D~4D | |

| Iimfuno zokucubungula | Uluhlu lokuphakama komngxuma | 35~100mm |

| Hi-oleububanzi amananikumzila ngamnye wesitimela | 1~4 iintlobo | |

| Ivumelekileukunyamezelanaisithuba somngxuma okufutshane | ± 0.3mm | |

| Ivumelekileukunyamezelanaphakathi kobuso besiphelo sesitimela kunye nomgama okufutshane womngxuma | ± 0.5mm | |

| Ivumelekileukunyamezelanaumgama omde kakhulu wesitimela | ± 0.5mm | |

| Ivumelekileukunyamezelanayeububanzi bomngxumaubungakanani | 0~+0.3mm | |

| Uburhabaxa bodonga lwemingxunya | I-Ra12.5 | |

| Ivumelekileukunyamezelanayokuphakama kwesiphakathi somngxuma (ukusuka ezantsi kwereli) | ± 0.3mm | |

| Ikholamu ephathwayo (kubandakanya ukubholaingibhokisi yamandla) | Ubungakanani | Iseti e-1 |

| Umngxuma we-spindle taper | BT50 | |

| Uluhlu lwesantya se-spindle (ulawulo lwesantya olungenamagxathu) | 10~3200r/ngomzuzu | |

| Amandla enjini yeServo yeServo yeSpindle | 37kW | |

| Uhambo lweslayidi ethe nkqo (i-Y axis) | 800mm | |

| Amandla enjini ye-servo yeslayidi ethe nkqo (Y-axis) | 3.1kw | |

| I-stroke yokubhola ethe tye (i-axis Z) | 350mm | |

| I-feed yokubhola ethe tye (i-Z axis) amandla emoto ye-servo | 3.1kw | |

| I-stroke yokuhamba ethe tye yekholamu (i-axis ye-X) | 25m | |

| Intshukumo ethe tye yekholamu (i-X axis) amandla emoto ye-servo | 3.1kw | |

| Isantya esiphezulu sokuhamba se-X-axis | 10m/ngomzuzu | |

| Isantya esiphezulu sokuhamba se-axis Y, Z | 8m/ngomzuzu | |

| Isixhobo sokufaka umazibuthe esisisigxina sombane | Ubungakanani | Iseti e-1 |

| Ubungakanani besucker (L × w × h) | 250×200×120mm | |

| Ukufunxa okusebenzayo | ≥200N/cm² | |

| Isilinda sokutyhala ecaleni | Ububanzi besilinda × isibetho | Φ50×70mm |

| I-single cylinder side thrust | 700Kg | |

| Itafile eqengqelekayo yokuphakamisa | Ubungakanani | Iseti e-1 |

| Isantya sokuhambisa | ≤15m/ngomzuzu | |

| Isilinda esincedisayo sokubamba phantsi | Ubungakanani | Iseti e-1 |

| Amandla okucinezela | ≥1500Kg/iseti | |

| Ukususwa kweetships | Uhlobo lokuhambisa itshiphusi | Itsheyini ethe tyaba |

| Isantya sokususa iitships | 2m/ngomzuzu | |

| Amandla enjini yokususa iitships | 2.2kW | |

| Inkqubo ye-hydraulic | Ubungakanani | Iiseti ezi-2 |

| Uxinzelelo lwepompo ye-hydraulic / ukuhamba / amandla | 6-6.5Mpa/25L/min/4kW iseti e-1 | |

| Uxinzelelo lwepompo ye-hydraulic / ukuhamba / amandla | 5.5-6Mpa/66L/min/7.5kW iseti e-1 | |

| Inkqubo yombane | Inkqubo yolawulo lwamanani | I-Siemens 828D |

| Inani lee-axes ze-CNC | 5+1 | |

| Umthombo womoya | Uxinzelelo lomoya oluxinzelelweyo | 0.6Mpa |

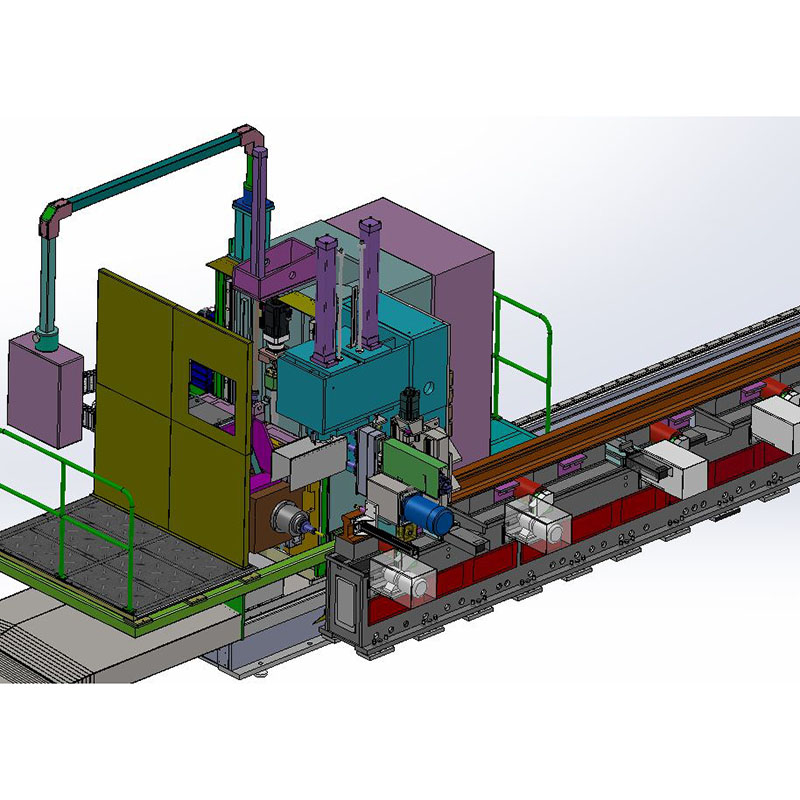

| Ubukhulu obupheleleyo | (L× W× H) | Malunga ne-57×8.7×3.8m |

1. Ibhedi yomatshini yahlulwe kwitafile yokusebenza, kwaye isibini sereli yesikhokelo sebhedi sicwangciswe ngokuthe tye ukuze kwandiswe ubomi benkonzo yesibini sereli yesikhokelo; Ulwakhiwo lwepleyiti yentsimbi edibeneyo luyasetyenziswa, kwaye ukuchaneka kunye nozinzo kuqinisekiswa ngokuqhoboshela, ukunciphisa uxinzelelo kunye nonyango lokwaluphala okwenziwayo.

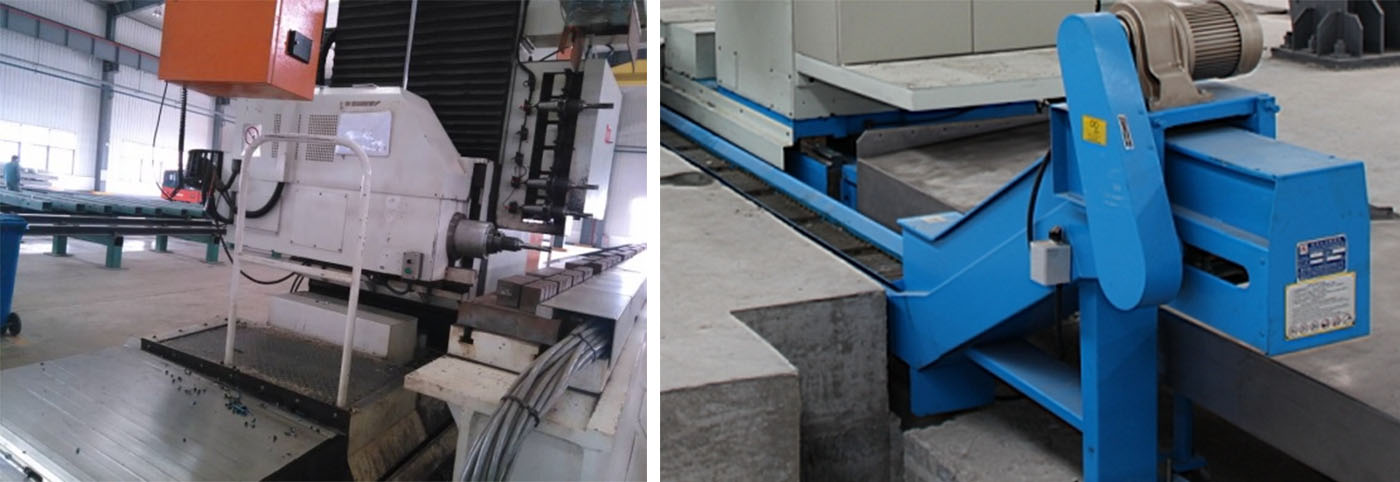

2. I-chuck enamandla ye-electromagnetic ifakelwe kwitafile yokusebenza yesixhobo somatshini ukuze iqine. Nika ingqalelo kulandelelwano oluvela embindini ukuya kumacala omabini xa i-sucker ye-electromagnetic ivaliwe, kwaye unike ingqalelo ekutywinweni nasekungangeni manzi.

3. Ikholamu eshukumayo isebenzisa isakhiwo sokuwelda sepleyiti yesinyithi, esifakwe i-anneal ukususa uxinzelelo kunye nonyango lokwaluphala okwenziwayo ukuqinisekisa uzinzo oluchanekileyo.

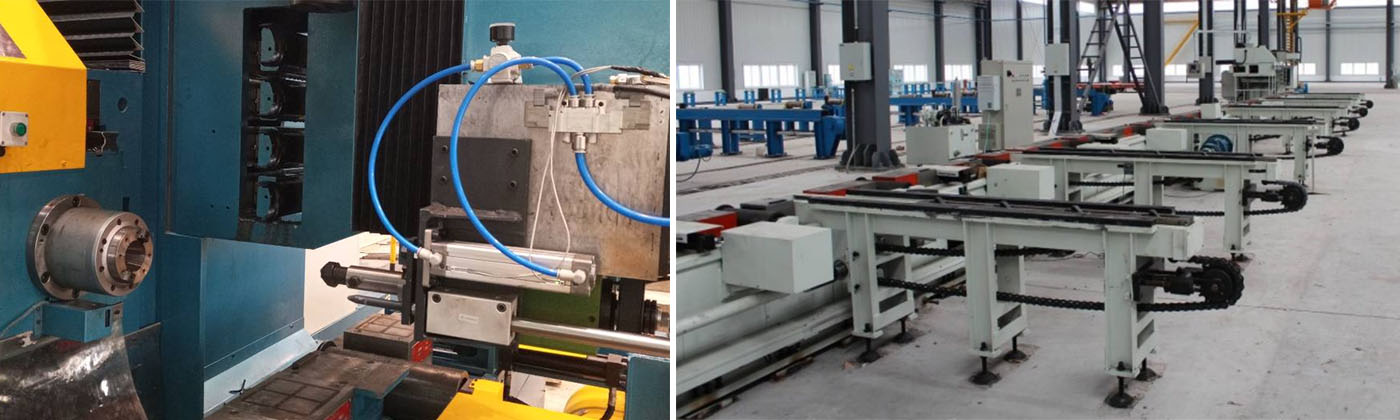

4. I-chain plate automatic chip remover iluhlobo lwe-flat chain, kwaye ifakwe embindini wetafile yokusebenza yebhedi.

5. Lo matshini uxhotyiswe ngezikhululo ezimbini ze-hydraulic, esinye sifakwe kwikholamu eshukumayo, esetyenziswa kakhulu ukulinganisela isilinda, isilinda esicinezelayo kunye nesilinda semela; Esinye sifakwe kwisiseko, esisetyenziswa kakhulu ukuphakamisa isilinda kunye nokutsala isilinda setafile yerola yokuphakamisa ehambisayo.

6. Kukho ii-axes ezintathu ze-CNC kumatshini, nganye kuzo ikhokelwa sisibini sesikhokelo sokuqengqeleka esichanekileyo.

7. Isixhobo sokugrumba sisebenzisa i-index able carbide u drill, kwaye i-spindle ipholiswa yi-air inkungu.

8. Inkqubo ye-CNC ye-Siemens 828D isetyenziswa kwinkqubo ye-CNC, enokujonga inkqubo yokugrumba ngexesha langempela.

| NO. | Igama | Uphawu | Ilizwe |

| 1 | Isibini sesikhokelo sebhola | I-HIWIN/PMI | ITaiwan (eTshayina) |

| 2 | I-CNCinkqubo | I-Siemens 828D | Jemani |

| 3 | Simoto ye-ervo | I-Siemens | Jemani |

| 4 | Ivalvu ye-hydraulic | I-ATOS | ElamaTaliyane |

| 5 | Impompo yeoyile | I-Justmark | ITaiwan (eTshayina) |

| 6 | Itsheyini yokurhuqa | II-GUS/CPS | IJamani / iKorea |

| 7 | Injini ye-servo ye-Spindle | I-Siemens | Jemani |

| 8 | Umnciphisi | I-ATLANTA | Jemani |

| 9 | I-spindle echanekileyo | UKenturn | ITaiwan (eTshayina) |

Qaphela: Lo ungentla ngumthengisi wethu oqhelekileyo. Ingatshintshwa zizinto ezifanayo ezisemgangathweni zolunye uphawu ukuba umthengisi ongentla akanakukwazi ukubonelela ngezixhobo xa kukho into ekhethekileyo.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba