Umatshini wokuBetha we-PPL1255 CNC weePlate ezisetyenziselwa iiBhari zeChassis zeLori

| HAYI. | IGAMA | IINKCUKACHA | |

| 1 | Izinto zepleyiti yetshasi yelori/yelori | Ipleyitiubukhulu | Ubude:4000~12000mm |

| Ububanzi:250~550mm | |||

| Ubukhulu:4~12mm | |||

| Ubunzima:≤600kg | |||

| Uluhlu lobubanzi be-punch:i-φ9~φ60mm | |||

| 2 | Umatshini wokubhoboza we-CNC (i-Y axis) | Uxinzelelo Oluqhelekileyo | 1200kN |

| Ubungakanani be-punch die | 25 | ||

| I-axis ka-Yisifo sohlangothi | malunga ne-630mm | ||

| Isantya esiphezulu se-axis ye-Y | 30m/ngomzuzu | ||

| Amandla emoto yeServo | 11kW | ||

| Ibhlokoisifo sohlangothi | 180mm | ||

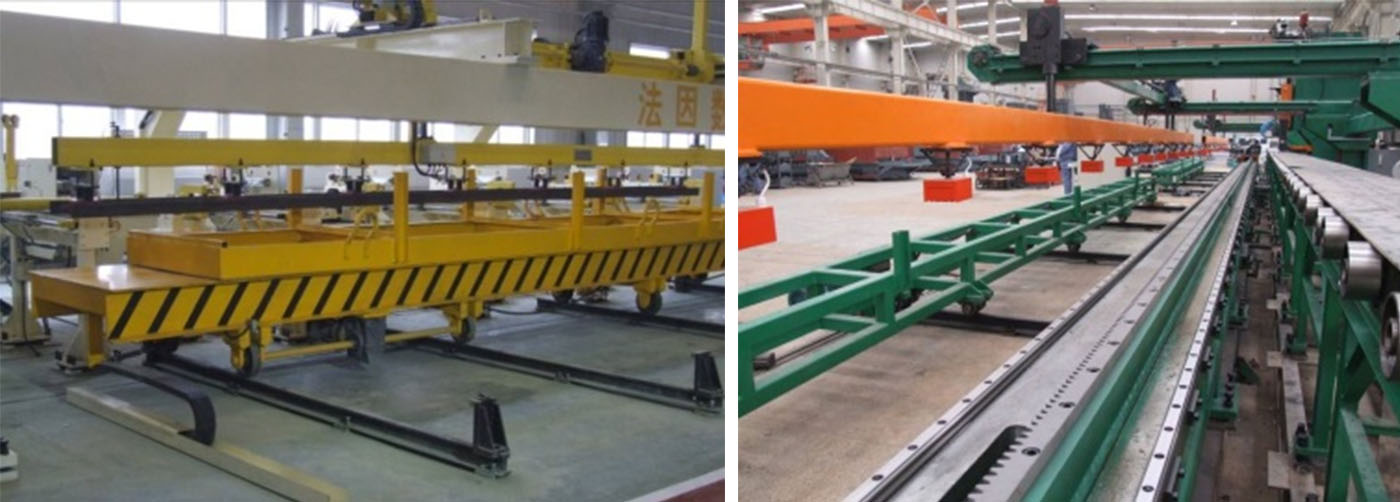

| 3 | Iyunithi yokulayisha enemagnethi | Ukuhamba kwenqanabaisifo sohlangothi | malunga ne-1800mm |

| Ukuhamba ngokuthe nkqoisifo sohlangothi | Malunga ne-500mm | ||

| Amandla enjini asemgangathweni | 0.75kW | ||

| Amandla enjini ethe nkqo | 2.2k | ||

| Ubungakanani beMagnetic | 10 ii-pcs | ||

| 4 | Iyunithi yokondla ye-CNC (i-X axis) | Uhambo lwe-X axis | Malunga ne-14400mm |

| Isantya esiphezulu se-axis X | 40m/ngomzuzu | ||

| Amandla emoto yeServo | 5.5kW | ||

| Ubungakanani bokubopha nge-hydraulic | 7 ii-pcs | ||

| Amandla okubamba | 20kN | ||

| Uhambo lokuvula i-clamp | 50mm | ||

| Uhambo lokwandisa i-clamp | Malunga ne-165mm | ||

| 5 | Ukondla umthuthi | Ukuphakama kokutya | 800mm |

| Ubude bokutya | ≤13000mm | ||

| Ubude bokutya ngaphandle | ≤13000mm | ||

| 6 | Iyunithi yokutyhala | Ubungakananii-ity | Iqela le-6 |

| Uhambo | malunga ne-450mm | ||

| Dudula | 900N/ iqela | ||

| 7 | Einkqubo yombane | Amandla apheleleyo | malunga nama-85kW |

| 8 | Umgca wemveliso | Ubude x ububanzi x ukuphakama | malunga ne-27000×8500×3400mm |

| Ubunzima obupheleleyo | malunga ne-44000kg | ||

1. Ukutyhala ecaleni, ukulinganisa ububanzi bephepha lesinyithi kunye nendlela yokubeka isiseko ngokuzenzekelayo: Ezi ndlela zineteknoloji enelungelo lobunikazi kwaye zichanekile kakhulu kwaye ziluncedo ekufakeni nasekulungiseni ngokulula, iphepha lesinyithi linokubekwa ecaleni kwephepha lesinyithi.

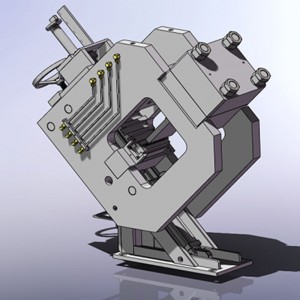

Iyunithi ephambili yokubhoboza: Umzimba womatshini yifreyimu evulekileyo yohlobo C, kulula ukuyilungisa. Indlela yokucinezela i-hydraulic stripper kunye nendlela yokukhuhla i-punch zisebenza kunye ukuphepha ibhloko yeshiti yesinyithi, ukuqinisekisa ukhuseleko lomatshini.

3. Indlela yokutshintsha ngokukhawuleza i-punch kunye ne-die: Le ndlela yobuchwepheshe kunye ne-punch ezinelungelo lobunikazi kwaye inokutshintshwa ngexesha elifutshane kakhulu, ithathelwe indawo enye okanye yonke iseti ngexesha.

| NO. | Igama | Uphawu | Ilizwe |

| 1 | Isilinda esebenza kabini | I-SMC/FESTO | IJapan / iJamani |

| 2 | Isilinda sengxowa yomoya | I-FESTO | Jemani |

| 3 | Ivalvu yeSolenoid kunye notshintsho loxinzelelo, njl.. | I-SMC/FESTO | IJapan / iJamani |

| 4 | Isilinda esiphambili se-punch | iTshayina | |

| 5 | Izinto eziphambili ze-hydraulic | I-ATOS | ElamaTaliyane |

| 6 | isitishi sesikhokelo esithe ngqo | I-HIWIN/PMI | ITaiwan, iTshayina(I-axis ka-Y) |

| 7 | isitishi sesikhokelo esithe ngqo | I-HIWIN/PMI | ITaiwan, iTshayina(I-axis ye-X) |

| 8 | Ukudibanisa okuthambileyo ngaphandle kokubuyela umva | I-KTR | Jemani |

| 9 | Isixhobo sokunciphisa, izixhobo zokususa ukungcola kunye nerakhi | I-ATLANTA | Jemani (I-axis ye-X) |

| 10 | Itsheyini yokurhuqa | Igus | Jemani |

| 11 | Injini yeServo kunye nomqhubi | Yaskawa | Japhan |

| 12 | Isiguquli sefrikhwensi | I-Rexroth/ Siemens | Jemani |

| 13 | I-CPU kunye neemodyuli ezahlukeneyo | IMitsubishi | Japhan |

| 14 | Isikrini esibanjwayo | IMitsubishi | Japhan |

| 15 | Isixhobo sokuthambisa esizenzekelayo | IHerg | Japhan(Ioyile encinci) |

| 16 | Ikhompyutha | ILenovo | iTshayina |

| 17 | Isipholisi seoyile | Ukubhabha | iTshayina |

Qaphela: Lo ungentla ngumthengisi wethu oqhelekileyo. Ingatshintshwa zizinto ezifanayo ezisemgangathweni zolunye uphawu ukuba umthengisi ongentla akanakukwazi ukubonelela ngezixhobo xa kukho into ekhethekileyo.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba