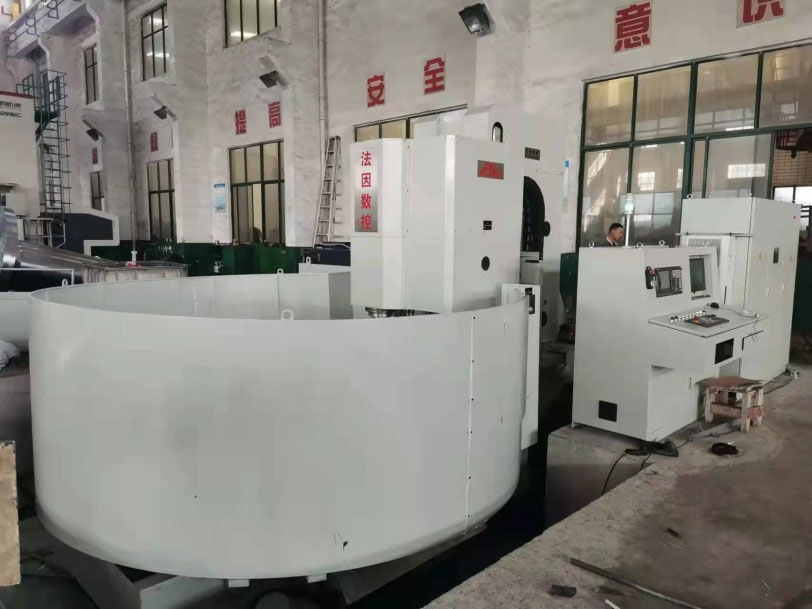

Umatshini wokubhola we-PM Series Gantry CNC (iRotary Machining)

| NO | Into | Ipharamitha | |||

| PM20A | PM25B | PM30B | |||

| 1 | Ubungakanani obukhulu bezinto ezibonakalayo | Ubukhulu bokucubungula | Φ800~Φ2000mm | φ1000~φ2500mm | φ1300~φ3000mm |

| Ubuninziizintoubukhulu | 300 mm | ||||

| 2 | Itafile ejikelezayo (C-axis) uxinzelelo olungaguqukiyo | Ububanzi betafile ejikelezayo | 2000mm | Ф2500 mm | Ф3000 mm |

| Ububanzi be-T-slot | 36 mm | ||||

| Lethwele i-oad | 3T/m | 30T | 40T | ||

| Misela ubuncinci beyunithi yokubonisa | 0.001° | ||||

| Isantya sokujikeleza se-C-axis | 0-1r/ngomzuzu | ||||

| Ukuchaneka kokubeka i-C-axis | 8"(Ukwenziwa ngokwezifiso okukhethekileyo) | ||||

| Ukuchaneka kokubeka kwakhona kwe-C-axis | 4"(Ukwenziwa ngokwezifiso okukhethekileyo) | ||||

| Ubunzima | Iitoni ezili-17 | Iitoni ezili-17 | Iitoni ezili-19 | ||

| 3 | Intloko yentloko | Ububanzi obukhulu bomngxuma | Φ96mm | Φ60 mm(Ukubhola ngekhabhayithi) | Φ70 mm(Ukubhola ngekhabhayithi) |

| Ububanzi obukhulu bokuthepha | I-M30 | M45 | M56 | ||

| Isantya esiphezulu se-spindle | 3000r/ngomzuzu | 2000r/ngomzuzu | |||

| I-spindle taper | BT50 | ||||

| Amandla enjini ye-spindle | 45KW | 30/41kW | 30/45kW | ||

| I-torque ephezulu ye-spindle ≤ 250r / min | 1140/1560Nm | ||||

| Ibhokisi eguquguqukayo | 1:1.2/1:4.8 | ||||

| Umgama phakathi kobuso besiphelo se-spindle kunye netafile ejikelezayo | 400-900mm | 400-1050mm | |||

| Umgama ukusuka kwi-axis ye-spindle ukuya kwiziko letafile elijikelezayo | 500-1700mm | 650-1850mm | |||

| 4 | Inkqubo ye-hydraulic | Uxinzelelo/ukuhamba kwepompo ye-hydraulic | 6.5Mpa/25L/ngomzuzu | ||

| Amandla enjini yepompo ye-hydraulic | 3KW | ||||

| 5 | Inkqubo yombane | Inkqubo yolawulo lwamanani | I-Siemens 828D | ||

| Inani lee-axes ze-CNC | 3+1 | 3+1 | 3+1 | ||

| Amandla apheleleyo emoto | malunga75kW | malunga ne-50kW | malunga ne-70kW | ||

| 6 | Ubukhulu bomatshini (L*W*H) | Amalunga ne-5.8*4.2*5m | malunga ne-6.3*4.7*5m | ||

| 7 | Makumamaubunzima besiTshayina | ≥Iitoni ezili-17 | Umatshini: I-turret ye-hydrostatic engama-20T:17T | Umatshini: 20T I-turret emanzi:19T | |

1. Umatshini ubunjwe ikakhulu yibhedi kunye ne-longitudinal slide, i-gantry kunye ne-transverse slide, i-automatic clamping chuck, intloko yokubhola ye-ram ethe nkqo, inkqubo ye-hydraulic, inkqubo yokupholisa, inkqubo yombane, i-automatic lubrication kunye nezinye iindawo.

2. I-ram eqondisa u-Z ifakwe ngokuthe nkqo kwislayidi eqondisa u-Y, ekhokelwa ziipaya zesikhokelo se-linear roller kumacala omabini e-ram, eqhutywa yi-lead screw pair eqhutywa yi-servo motor, kwaye ilinganiswe yi-hydraulic cylinder.

3. Intloko yokubhola ye-hydraulic hydraulic drilling head ethe nkqo ye-Z-direction ye-moving gantry ifakelwe kwipleyiti yesilayidi esihambayo ye-Y-direction ye-moving gantry ukuze ilungelelaniswe. Intloko yokubhola isebenzisa i-motor ekhethekileyo yokuguqula i-spindle kwaye iqhube i-spindle ngebhanti ehambelanayo. Ine-torque enkulu enesantya esiphantsi kwaye inokuthwala umthwalo onzima wokusika. Ikwafanelekile ekucubunguleni izixhobo ze-carbide ngesantya esiphezulu.

4. I-Taiwan precision spindle (ukupholisa kwangaphakathi) yamkelwe kwi-spindle yokubhola yalo matshini. I-spindle taper hole BT50 ine-butterfly spring automatic broach mechanism.

5. I-automatic clamping chuck isetyenziselwa ukubamba izinto ezi-annular ngokuzenzekelayo, kwaye amandla okubamba kulula ukuwalungisa. I-chuck yahlulwe ebhedini ukuze ikwazi ukubamba ngokukhawuleza ngokuzenzekelayo nokusebenza ngokuthembekileyo.

6. Iireli zesikhokelo ze-X-axis kumacala omabini omatshini zifakelwe isigqubuthelo sokukhusela sentsimbi engagqwaliyo, kwaye iireli zesikhokelo ze-Y-axis zifakelwe isigqubuthelo sokukhusela esiguquguqukayo kuzo zombini iziphelo, esinomsebenzi othambileyo womda.

7. Umatshini uxhotyiswe nge-flat chain chip conveyor, ibhokisi yokufumana iitships iluhlobo lwe-flip, kunye nenkqubo yokupholisa ene-paper filter, kwaye i-coolant iyaphinda isetyenziswe.

8. Inkqubo ye-CNC yalo matshini isebenzisa iSpanish FAGOR8055, enevili lesandla le-elektroniki, umsebenzi onamandla kunye nokusebenza okulula. Ixhotyiswe ngekhompyutha ephezulu kunye ne-RS232 interface, kwaye inemisebenzi yokucubungula i-preview kunye nokuhlolwa. I-operation interface inemisebenzi ye-man-machine dialogue, i-error compensation kunye ne-alamu ezenzekelayo.

| NO | Igama | Uphawu | Ilizwe |

| 1 | Isikhokelo somgca we-roller | HIWIN | ITaiwan, iTshayina |

| 2 | Isikrufu sebhola | I-NEFF/IF | Jemani |

| 3 | Itafile ejikelezayo ye-Ф 2500 (uxinzelelo olungaguqukiyo) | Iqela loMatshini weZixhobo zeJIER | iTshayina |

| 4 | Inkqubo yolawulo lwamanani | I-Siemens 828D | Jemani |

| 5 | I-servo motor kunye nomqhubi wokutya | I-Siemens | Jemani |

| 6 | Injini ephambili | I-Siemens | Jemani |

| 7 | Umlawuli wegrating | I-FAGOR | Speyin |

| 8 | I-Spindle | UKenturn | ITaiwan, iTshayina |

| 9 | Ivalvu ye-hydraulic | I-ATOS | ElamaTaliyane |

| 10 | Impompo yeoyile | I-Justmark | ITaiwan, iTshayina |

| 11 | Inkqubo yokuthambisa ezenzekelayo | I-BIJUR | i-USA |

| 12 | Impompo yokupholisa | Iimpompo zeFengchao | iTshayina |

| 13 | Iqhosha, isibane sesalathisi kunye nezinye izinto eziphambili zombane | USchneider | Fransi |

| 14 | Tityala lokukhupha abantu | I-GTP | ITaiwan, iTshayina |

Qaphela: Lo ungentla ngumthengisi wethu oqhelekileyo. Ingatshintshwa zizinto ezifanayo ezisemgangathweni zolunye uphawu ukuba umthengisi ongentla akanakukwazi ukubonelela ngezixhobo xa kukho into ekhethekileyo.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba