Umatshini wokubhola iPlati ye-CNC yeGantry eshukumayo ye-PLM4020

(1) Umzimba wesakhelo somatshini kunye nomqadi onqamlezileyo zenziwe ngesakhiwo esenziwe nge-welded, emva konyango lobushushu olwaneleyo, ngokuchanekileyo okukhulu. Itafile yokusebenza, itafile yokutyibilika enqamlezileyo kunye ne-ram zonke zenziwe ngentsimbi ephothiweyo.

(2) Inkqubo yokuqhuba i-servo emacala mabini kwi-X axis iqinisekisa intshukumo echanekileyo ye-gantry, kunye nesikwere esihle se-Y axis kunye ne-X axis.

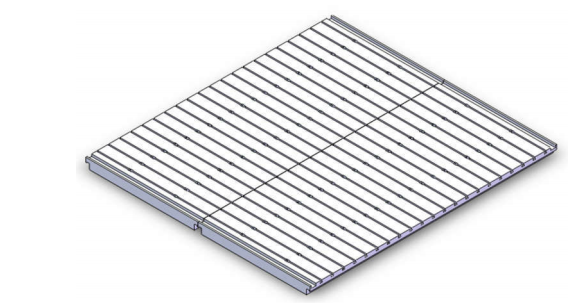

(3) Itheyibhile yokusebenza isebenzisa uhlobo oluzinzileyo, isinyithi esisemgangathweni ophezulu kunye nenkqubo yokuphosa ephucukileyo, enomthamo omkhulu wokuthwala.

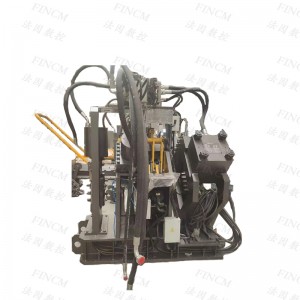

(4) Isihlalo sokuthwala esiqinileyo, ibhereyitha isebenzisa indlela yokufaka engasemva, ibhereyitha ekhethekileyo enezikrufu ezichanekileyo.

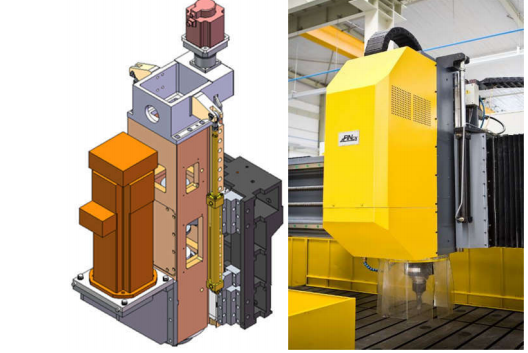

(5) Intshukumo ethe nkqo (i-Z-axis) yentloko yamandla ikhokelwa zizibini zesikhokelo ezijikelezayo ezicwangciswe kumacala omabini e-ram, echanekileyo kakuhle, ukumelana nokungcangcazela okuphezulu kunye ne-coefficient ephantsi yokungqubana.

(6) Ibhokisi yamandla okubhola yeyohlobo lwe-spindle echanekileyo, eyamkela i-spindle yangaphakathi yokupholisa yaseTaiwan BT50. Umngxuma we-spindle cone unesixhobo sokucoca, kwaye ungasebenzisa i-carbide cemented internal cooling drill, ngocoselelo oluphezulu. I-spindle iqhutywa yi-spindle servo motor enamandla aphezulu ngebhanti ehambelanayo, umlinganiselo wokunciphisa yi-2.0, isantya se-spindle yi-30~3000r/min, kwaye uluhlu lwesantya lubanzi.

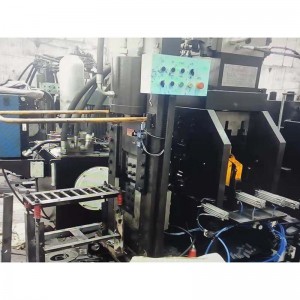

(7) Umatshini usebenzisa izisusi ezimbini ze-flat chain chips kumacala omabini etafile yokusebenza. Ii-iron chips kunye ne-coolant ziqokelelwa kwi-chip remover. Ii-iron chips zithuthwa zisiwe kwi-chip carrier, ekulula kakhulu ukuyisusa. I-coolant iyaphinda isetyenziswe.

(8) Lo matshini ubonelela ngeendlela ezimbini zokupholisa - ukupholisa ngaphakathi kunye nokupholisa ngaphandle. Impompo yamanzi enoxinzelelo oluphezulu isetyenziselwa ukubonelela ngesipholisi esifunekayo ekupholiseni ngaphakathi, ngoxinzelelo oluphezulu kunye nokuhamba okukhulu.

(9) Lo matshini uxhotyiswe ngenkqubo yokuthambisa ezenzekelayo, epompa ioyile yokuthambisa kwibhloko yokutyibiliza ye-linear guide pair, i-ball screw pair screw nut kunye ne-rolling bearing yenxalenye nganye rhoqo ukuze kwenziwe ukuthambisa okwaneleyo nokuthembekileyo.

(10) Iireli zesikhokelo ze-X-axis kumacala omabini omatshini zixhotyiswe ngezigqubuthelo zokukhusela zentsimbi engagqwaliyo, kwaye iireli zesikhokelo ze-Y-axis zifakelwe izigqubuthelo zokukhusela eziguquguqukayo.

(11) Isixhobo somatshini sikwaxhotyiswe ngesixhobo sokufumana umphetho we-photoelectric ukuze kube lula ukubeka izinto zokusebenza ezijikelezileyo.

(12) Isixhobo somatshini siyilwe kwaye sifakelwe izixhobo zokhuseleko ezipheleleyo. Umqadi we-gantry uxhotyiswe ngeqonga lokuhamba, i-guardrail, kunye neleli yokunyuka ecaleni kwekholamu ukuqinisekisa ukhuseleko lwabasebenzi bokusebenza kunye nolondolozo. Isiciko se-PVC esicacileyo esithambileyo sifakwe sijikeleze umngxuma ophambili.

(13) Inkqubo ye-CNC ixhotyiswe nge-Siemens 808D okanye i-Fagor 8055, enemisebenzi enamandla. I-interface yokusebenza inemisebenzi yencoko yoomatshini, imbuyekezo yeempazamo kunye ne-alamu ezenzekelayo. Inkqubo ixhotyiswe nge-electronic handwheel, elula ukuyisebenzisa. Ixhotyiswe ngekhompyutha ephathekayo, inkqubo ezenzekelayo ye-CAD-CAM inokuphunyezwa emva kokuba isoftware ephezulu yekhompyutha ifakiwe.

| Into | Igama | Ixabiso |

|---|---|---|

| Ubungakanani obukhulu bePlate | L x W | 4000×2000 mm |

| Ubungakanani obukhulu bePlate | Ububanzi | Φ2000mm |

| Ubungakanani obukhulu bePlate | Ubukhulu obukhulu | 200 mm |

| Itheyibhile Yomsebenzi | Ububanzi beSlot T | 28 mm (eqhelekileyo) |

| Itheyibhile Yomsebenzi | Ubukhulu betafile yomsebenzi | 4500x2000mm (LxW) |

| Itheyibhile Yomsebenzi | Ukulayisha Ubunzima | Iitoni ezi-3/㎡ |

| I-Spindle yokubhola | Ububanzi obukhulu bokubhola | Φ60 mm |

| I-Spindle yokubhola | Ububanzi obukhulu bokuthepha | I-M30 |

| I-Spindle yokubhola | Ubude bentonga yokubhola uthelekisa nobubanzi bemingxuma | ≤10 |

| I-Spindle yokubhola | I-RPM | 30~3000 r/min |

| I-Spindle yokubhola | Uhlobo lweTape yeSpindle | BT50 |

| I-Spindle yokubhola | Amandla enjini ye-spindle | 22kW |

| I-Spindle yokubhola | I-Torque ephezulu (n≤750r/min) | 280Nm |

| I-Spindle yokubhola | Umgama ukusuka kumphezulu osezantsi weSpindle ukuya kwitafile yokusebenza | 280 ~ 780 mm (ingahlengahlengiswa ngokobukhulu bezinto ezibonakalayo) |

| Intshukumo ye-Gantry Longitudinal (X Axis) | Uhambo oluphezulu | 4000 mm |

| Intshukumo ye-Gantry Longitudinal (X Axis) | Isantya sokuhamba ecaleni kwe-X axis | 0~10m/ngomzuzu |

| Intshukumo ye-Gantry Longitudinal (X Axis) | Amandla enjini yeServo ye-X axis | 2×2.5kW |

| Intshukumo Eguqukayo Yesipindle (Y Axis) | Uhambo oluphezulu | 2000mm |

| Intshukumo Eguqukayo Yesipindle (Y Axis) | Isantya sokuhamba ecaleni kwe-Y axis | 0~10m/ngomzuzu |

| Intshukumo Eguqukayo Yesipindle (Y Axis) | Amandla enjini yeServo ye-Y axis | 1.5kW |

| Intshukumo Yokutya Yesipindle (Z Axis) | Uhambo oluphezulu | 500 mm |

| Intshukumo Yokutya Yesipindle (Z Axis) | Isantya sokondla se-axis Z | 0~5m/ngomzuzu |

| Intshukumo Yokutya Yesipindle (Z Axis) | Amandla enjini yeServo ye-axis ye-Z | 2kW |

| Ukuchaneka kokubeka indawo | I-axis X, i-axis Y | 0.08/0.05mm/uhambo olupheleleyo |

| Ukuchaneka kokubeka okuphindaphindwayo | I-axis X, i-axis Y | 0.04/0.025mm/uhambo olupheleleyo |

| Inkqubo ye-hydraulic | Uxinzelelo lwepompo ye-hydraulic/Isantya sokuhamba kwamanzi | 15MPa /25L/ngomzuzu |

| Inkqubo ye-hydraulic | Amandla emoto yepompo ye-hydraulic | 3.0kW |

| Inkqubo yomoya | Uxinzelelo lomoya oluxinzelelweyo | 0.5 MPa |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Uhlobo lokususa iimfumba | Ikhonkco lepleyiti |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Iinombolo zokususa iiskraphu. | 2 |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Isantya sokususa iiskraphu | 1m/ngomzuzu |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Amandla eMoto | 2×0.75kW |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Indlela yokupholisa | Ukupholisa ngaphakathi + Ukupholisa ngaphandle |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Uxinzelelo Oluphezulu | 2MPa |

| Ukususwa kweengceba kunye nenkqubo yokupholisa | Izinga eliphezulu lokuhamba kwamanzi | 50L/ngomzuzu |

| Inkqubo ye-elektroniki | Inkqubo yolawulo lwe-CNC | I-Siemens 808D |

| Inkqubo ye-elektroniki | Iinombolo ze-CNC Axis | 4 |

| Inkqubo ye-elektroniki | Amandla apheleleyo | Malunga ne-35kW |

| Ubukhulu obupheleleyo | L×W×H | Malunga ne-10×7×3m |

| Hayi. | Igama | Uphawu | Ilizwe |

|---|---|---|---|

| 1 | Isikhokelo sikaloliwe esijikelezayo esijikelezayo | Hiwin | iTshayina iTaiwan |

| 2 | Inkqubo yolawulo lwe-CNC | I-Siemens/ Fagor | IJamani/iSpain |

| 3 | Ukondla i-servo motor kunye nomqhubi we-servo | I-Siemens/Panasonic | IJamani/iJapan |

| 4 | I-spindle echanekileyo | I-Spintech/Kenturn | iTshayina iTaiwan |

| 5 | Ivalvu ye-hydraulic | Yuken/Justmark | IJapan/iTshayina iTaiwan |

| 6 | Impompo yeoyile | I-Justmark | iTshayina iTaiwan |

| 7 | Inkqubo yokuthambisa ezenzekelayo | IHerg/BIJUR | IJapan/iMelika |

| 8 | Iqhosha, Isalathisi, izixhobo ze-elektroniki ezisebenzisa umbane ophantsi | ABB/Schneider | IJamani/iFransi |

| Hayi. | Igama | Ubungakanani | Ubungakanani. |

|---|---|---|---|

| 1 | Isixhobo sokufumana umphetho obonakalayo | Isiqwenga esi-1 | |

| 2 | Isitshixo seheksagoni yangaphakathi | Iseti e-1 | |

| 3 | Isibambi sezixhobo kunye nestud yokutsala | Φ40-BT50 | Isiqwenga esi-1 |

| 4 | Isibambi sezixhobo kunye nestud yokutsala | Φ20-BT50 | Isiqwenga esi-1 |

| 5 | Iipeyinti ezingasetyenziswanga | – | Iikegi ezi-2 |

1. Ubonelelo lwamandla: izigaba ezi-3 imigca emi-5 380+10%V 50+1HZ

2. Uxinzelelo lomoya oluxinzelelweyo: 0.5MPa

3.Ubushushu: 0-40℃

4. Umswakama: ≤75%