Umatshini wokugrumba inqwelo moya yeselula ye-PEM Series Gantry CNC

| Into | Igama | Ixabiso | |||||||

| I-PEM3030-2 | I-PEM4040-2 | I-PPEM5050-2 | PEM6060-2 | ||||||

| UbuninziIpleyiti izintoUbungakanani | L x W | 3000*3000 mm | 4000*4000mm | 5000×5000 mm | 6000×6000 mm | ||||

| Ubukhulu bezinto ezibonakalayo | 250 mm (Ingandiswa ibe yi-380mm) | ||||||||

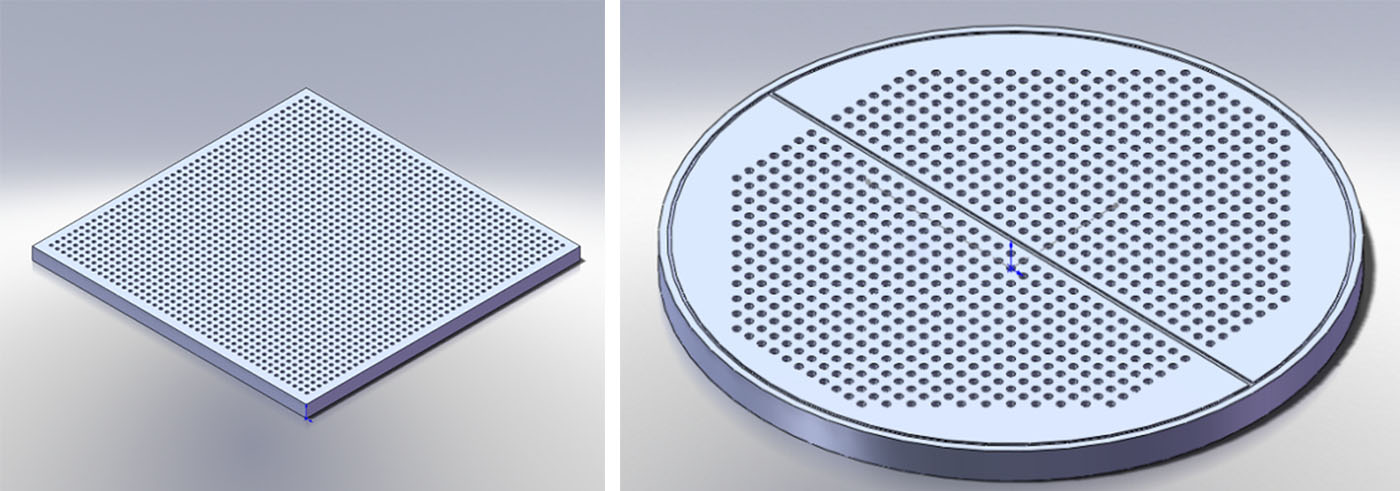

| Itheyibhile Yomsebenzi | Ububanzi beSlot T | 28 mm (eqhelekileyo) | |||||||

| Ukulayisha Ubunzima | Iitoni ezi-3/ | ||||||||

| I-Spindle yokubhola | Ububanzi obukhulu bokubhola | Φ50 mm | |||||||

| Ubude bentonga yespindle yokubholakunyeUbubanzi bomngxuma | ≤10 | ||||||||

| Iteyiphu yeSpindle | BT50 | ||||||||

| Amandla enjini ye-spindle | 2*18.5kw/22kw | ||||||||

| Umgama ukusuka kumphezulu osezantsi weSpindle ukuya kwitafile yokusebenza | 280~780 mm (inokuhlengahlengiswa ngokobukhulu bezinto ezibonakalayo) | ||||||||

| Ukuchaneka kokubeka indawo | I-axis ka-X,I-axis ka-Y | 0.06mm/ igcweleisifo sohlangothi | 0.10mm/ igcweleisifo sohlangothi | 0.12mm/ igcweleisifo sohlangothi | |||||

| Ukuchaneka kokubeka okuphindaphindwayo | I-axis ka-X,I-axis ka-Y | 0.035mm/epheleleyoisifo sohlangothi | 0.04mm/epheleleyoisifo sohlangothi | 0.05mm/uhambo olupheleleyo | 0.06mm/uhambo olupheleleyo | ||||

| Inkqubo ye-hydraulic | Uxinzelelo lwepompo ye-hydraulic/ Umgangatho wohambo | 15MPa /22L/min | |||||||

| Amandla emoto yepompo ye-hydraulic | 3 kW | ||||||||

| Inkqubo yomoya | Uxinzelelo lomoya oluxinzelelweyo | 0.5 MPa | |||||||

| ItshiphuInkqubo yokususa kunye neyokupholisa | Itshiphuukususwa kwe-type | Ikhonkco lepleyiti | |||||||

| Itshiphuukususwa Ninombolo | 2 | ||||||||

| Itshiphuisantya sokususa | 1m/ngomzuzu | ||||||||

| Amandla eMoto | 2×0.75kW | ||||||||

| Indlela yokupholisa | Ukupholisa ngaphakathi + Ukupholisa ngaphandle | ||||||||

| Uxinzelelo Oluphezulu | 2MPa | ||||||||

| Izinga eliphezulu lokuhamba kwamanzi | 2*50L/ngomzuzu | ||||||||

| Inkqubo ye-elektroniki | Inkqubo ye-CNC | KND2000 | |||||||

| I-CNC Axis Ninombolo | 6 | ||||||||

| Amandla apheleleyo | Malunga ne-70kW | ||||||||

| Ubukhulu obupheleleyo | L×W×H | Malunga ne-7.8*6.7*4.1m | Amalunga 8.8*7.7*1.1m | Malunga9.8×7.7×4.1m | Malunga10.8×9.7×4.1m | ||||

| Ubunzima bomatshini | Malunga nama-22Iitoni | MalungaIitoni ezingama-30 | Malunga35tii-ons | Malunga45tii-ons | |||||

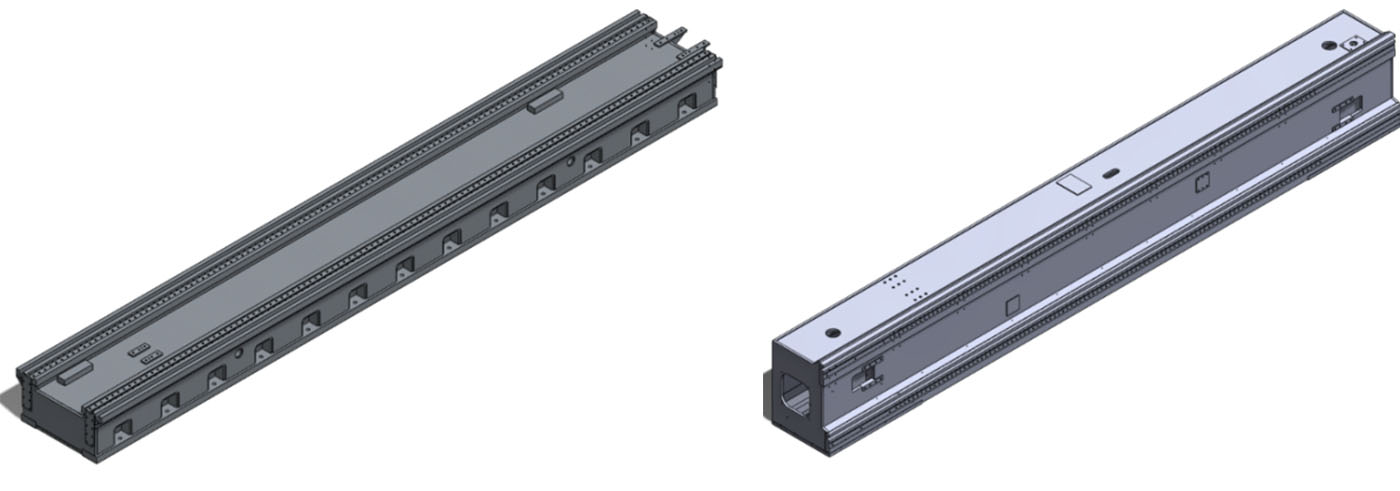

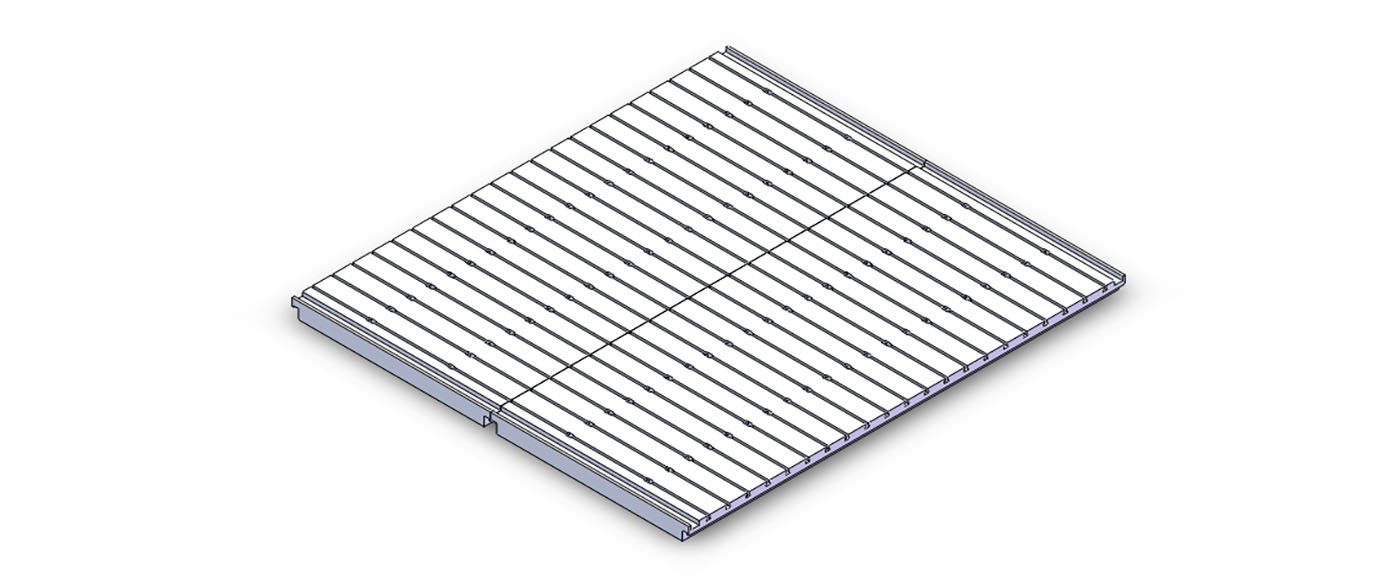

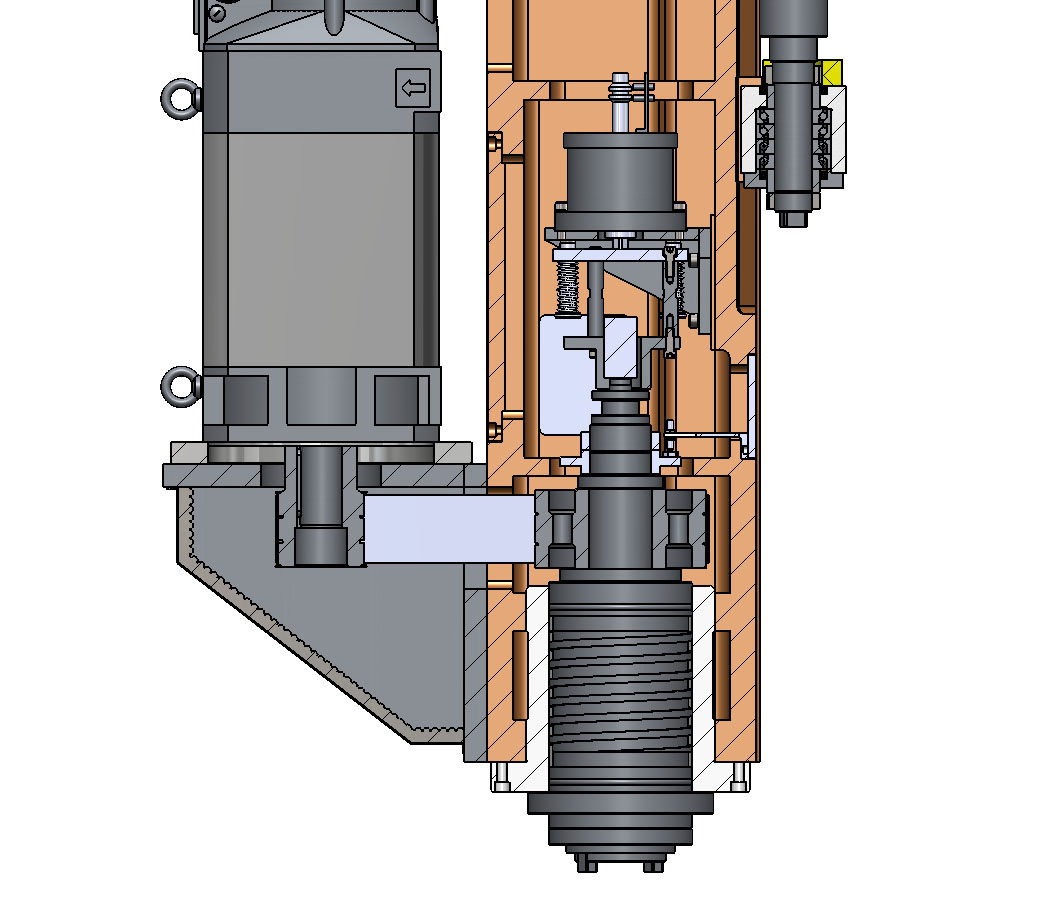

1. Lo matshini ubunjwe ikakhulu yibhedi kunye nekholamu, umqadi kunye netafile yokutyibilika ethe tye, ibhokisi yamandla okubhola yohlobo lwe-ram ethe nkqo, itafile yokusebenza, i-chip conveyor, inkqubo ye-hydraulic, inkqubo ye-pneumatic, inkqubo yokupholisa, inkqubo yokuthambisa ephakathi, inkqubo yombane, njl.njl.

2. Isihlalo sebhereyitha esiqinileyo, ibhereyitha isebenzisa isikrufu esichanekileyo kakhulu. Umphezulu wesiseko sokufaka omde kakhulu uqinisekisa ukuqina kwe-axial. Ibhereyitha iqiniswa kwangaphambili yi-lock nut, kwaye isikrufu se-lead siqiniswa kwangaphambili. Ubungakanani bokusolula bumiselwa ngokwenguquko yobushushu kunye nokwandiswa kwesikrufu se-lead ukuqinisekisa ukuba ukuchaneka kwendawo ye-lead screw akutshintshi emva kokuba ubushushu bunyukile.

3. Intshukumo ethe nkqo (i-Z-axis) yentloko yamandla ikhokelwa zizikhokelo ezimbini ze-linear roller ezicwangciswe kwi-ram, ezinobunono obuhle besikhokelo, ukumelana nokungcangcazela okuphezulu kunye ne-coefficient ephantsi yokungqubana. I-ball screw drive iqhutywa yi-servo motor nge-precision planetary reducer, enamandla aphezulu okutya.

4. Lo matshini usebenzisa ii-flat chain chip conveyors ezimbini kumacala omabini etafile yokusebenza. Ii-iron chips kunye ne-coolant ziqokelelwa kwi-chip conveyor, kwaye ii-iron chips zithuthwa ziye kwi-chip conveyor, elula kakhulu ukususa ii-chip; i-coolant iyaphinda isetyenziswe.

5. Lo matshini ubonelela ngeendlela ezimbini zokupholisa—ukupholisa ngaphakathi kunye nokupholisa ngaphandle, okubonelela nge-lubrication eyaneleyo kunye nokupholisa kwisixhobo kunye nezinto ngexesha lokusika iitships, okuqinisekisa ngcono umgangatho wokucubungula. Ibhokisi yokupholisa ixhotyiswe nge-liquid level find kunye ne-alamu components, kwaye uxinzelelo oluqhelekileyo lokupholisa yi-2MPa.

6. Iireli zesikhokelo ze-X-axis kumacala omabini omatshini zixhotyiswe ngezigqubuthelo zokukhusela zentsimbi engagqwaliyo, kwaye iireli zesikhokelo ze-Y-axis zixhotyiswe ngezigqubuthelo zokukhusela eziguquguqukayo kuzo zombini iziphelo.

7. Lo matshini uxhotyiswe ngesixhobo sokufumana umphetho we-photoelectric ukuze kube lula ukubeka izinto ezijikelezayo.

| HAYI. | INTO | UPHAWU | Imvelaphi |

| 1 | Isikhokelo sikaloliwe esijikelezayo esijikelezayo | HIWIN/CSK | iTshayina iTaiwan |

| 2 | Inkqubo yolawulo lwe-CNC | I-SIEMENS | Jemani |

| 3 | Ukondla i-servo motor kunye nomqhubi we-servo | I-SIEMENS | Jemani |

| 4 | I-spindle echanekileyo | I-SPINTECH/UKENTURN | iTshayina iTaiwan |

| 5 | Ivalvu ye-hydraulic | I-YUKEN/JUSTMARK | Japhan/ iTshayina iTaiwan |

| 6 | Impompo yeoyile | I-JUSTMARK | iTshayina iTaiwan |

| 7 | Inkqubo yokuthambisa ezenzekelayo | I-HERG | Japhan |

Qaphela: Lo ungentla ngumthengisi wethu oqhelekileyo. Ingatshintshwa zizinto ezifanayo ezisemgangathweni zolunye uphawu ukuba umthengisi ongentla akanakukwazi ukubonelela ngezixhobo xa kukho into ekhethekileyo.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba