Umenzi we-China SF8 FINCM Double Spindle Drilling Machine weSakhelo seLori

Umsebenzi wethu kukukhonza abasebenzisi bethu kunye nabathengi ngezinto zedijithali eziphathwayo ezikumgangatho ophezulu nezinoburhabaxa kuMenzi we-SF8 FINCM Double Spindle waseTshayina.Umatshini wokubholaKwiSakhelo seLori, Ngoku sinezisombululo ezine eziphambili. Iimpahla zethu zithengiswa kakhulu kungekuphela nje kwicandelo laseTshayina, kodwa zamkelwe nakwiimarike zamazwe ngamazwe.

Umsebenzi wethu kukukhonza abasebenzisi bethu kunye nabathengi ngezixhobo zedijithali ezisemgangathweni ophezulu nezinoburhabaxa.Umatshini wokugrumba isakhelo selori saseTshayina, Umatshini wokubhola, Zonke iimatshini ezingenisiweyo zilawula ngokufanelekileyo kwaye ziqinisekisa ukuchaneka koomatshini kwiimveliso. Ngaphandle koko, sineqela labasebenzi kunye neengcali zolawulo oluphezulu, abenza iimveliso ezikumgangatho ophezulu kwaye banakho ukuphuhlisa iimveliso ezintsha ukwandisa imakethi yethu ekhaya nakwamanye amazwe. Silindele ngokunyanisekileyo ukuba abathengi beze kwishishini eliqhakazileyo kuthi sobabini.

Iiparamitha zeMveliso

| Igama lepharamitha | Iyunithi | Ixabiso lepharamitha | ||

| Iiparamitha zenkqubo yesakhelo | Izinto eziphathekayo | Intsimbi eqengqelekayo eshushu eyi-16MnL | ||

| Amandla amakhulu okuxinana | I-MPa | 1000 | ||

| Unikeze Amandla | I-MPa | 700 | ||

| Ubukhulu obukhulu bokubhola | mm | 40 (ibhodi eneeleya ezininzi) | ||

| Ukucubungula i-stroke | i-axis | mm | 1600 | |

| I-axis ka-Y | mm | 1200 | ||

| Ukubambelela ecaleni kweselula | i-axis | mm | 500 | |

| I-Xaxis | mm | 500 | ||

| I-spindle yokubhola | ubungakanani | isiqwenga | 2 | |

| I-spindle taper | BT40 | |||

| Uluhlu lobubanzi bokubhola | mm | φ8~φ30 | ||

| Umgama omncinci wokubhola weentloko zamandla amabini ngaxeshanye | mm | 295 | ||

| I-Stroke yokutyisa | mm | 450 | ||

| Isantya esijikelezayo | r/min | 50~2000 (Servo engenasinyathelo) | ||

| Izinga lokutya | mm/umzuzu | 0~8300 (iServo engenasinyathelo) | ||

| Amandla enjini ye-servo ye-Spindle | kW | 2×7.5 | ||

| I-torque elinganiswe nge-Spindle | Nm | 150 | ||

| I-torque ye-spindle | Nm | 200 | ||

| Amandla aphezulu okutya okuphotha | N | 7500 | ||

| Imagazini yezixhobo | Ubungakanani | isiqwenga | 2 | |

| Ifomu yesiphatho | BT40 (Nge-drill eqhelekileyo ye-taper shank twist) | |||

| Ubungakanani besixhobo semagazini | isiqwenga | 2×4 | ||

| Inkqubo ye-CNC | Indlela yokulawula | Inkqubo ye-Siemens 840D SL CNC | ||

| Inani lee-axes ze-CNC | isiqwenga | 7+2 | ||

| Amandla emoto yeServo | I-Xaxis | kW | 4.3 | |

| I-axis ka-Y | 2×3.1 | |||

| I-axis ka-Z | 2×1.5 | |||

| I-Xaxis | 1.1 | |||

| I-Xaxis | 1.1 | |||

| Inkqubo ye-hydraulic | Uxinzelelo lokusebenza kwenkqubo | I-MPa | 2~7 | |

| inkqubo yokupholisa | Indlela yokupholisa | Indlela yokupholisa i-Aerosol | ||

Iinkcukacha kunye neenzuzo

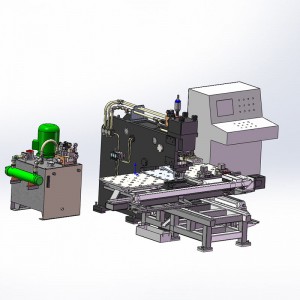

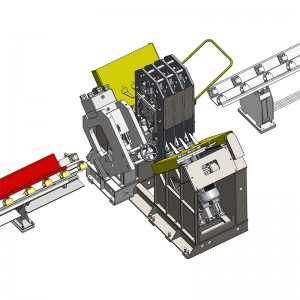

1. Umatshini oyintloko uquka ikakhulu ibhedi, i-gantry ehambayo, intloko yamandla okubhola (2) (yokubhola i-steel twist drill drill ekhawulezayo), indlela yokutshintsha izixhobo (2), indlela yokubeka, ukubopha kunye nokufumanisa, kunye netroli yokutya (2 A), inkqubo yokupholisa ephucukileyo, inkqubo ye-hydraulic, inkqubo ye-CNC, isigqubuthelo sokukhusela kunye nezinye iindawo.

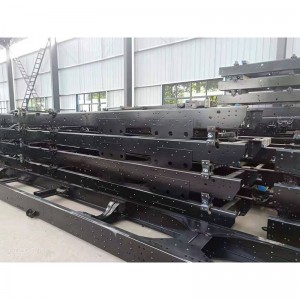

2. Umatshini usebenzisa uhlobo lwebhedi esisigxina kunye ne-gantry eshukumayo.

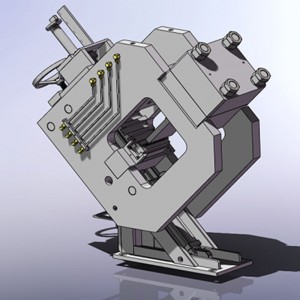

3. I-axis Y ethe tye kunye ne-axis Z ethe nkqo yeentloko ezimbini zamandla okubhola zihamba ngokuzimeleyo. Intshukumo ye-axis Y yentloko nganye yamandla iqhutywa sisikrufu esahlukileyo, esinokunqumla umgca osembindini wezinto; i-axis nganye ye-CNC ikhokelwa sisikhokelo sokuqengqeleka esithe tyaba. I-AC servo motor + i-ball screw drive. Intloko yamandla inoyilo oluchasene nokungqubana ukuthintela intloko yamandla ekungqubaneni ngexesha lokusebenza ngokuzenzekelayo.

4. Intloko yamandla okubhola isebenzisa i-spindle echanekileyo engeniswe ngaphakathi kwiziko lokugaya; ixhotyiswe ngomngxuma we-BT40 taper, kulula ukutshintsha isixhobo kwaye ingabotshelelwa kwiidrill ezahlukeneyo; i-spindle iqhutywa yi-servo spindle motor, enokuhlangabezana neemfuno zesantya esahlukeneyo kunye nemisebenzi yokutshintsha izixhobo.

5. Ukuze kuhlangatyezwane nokucutshungulwa kweendawo ezahlukeneyo zokuvula, umatshini uxhotyiswe ngeemagazini zezixhobo ezikwi-intanethi (2), kwaye iintloko ezimbini zamandla zinokutshintsha ngokuzenzekelayo izixhobo.

6. Lo matshini unesixhobo sokubona ngokuzenzekelayo esizimeleyo, esinokubona ngokuzenzekelayo ububanzi bezinto kwaye sibuyisele kwinkqubo ye-CNC.

7. Icala ngalinye lebhedi yomatshini lixhotyiswe ngeseti yokulungelelaniswa kwelaser ukuze ifreyimu ibekwe ngendlela erhabaxa.

9. Lo matshini uxhotyiswe ngenkqubo ye-hydraulic, esetyenziswa kakhulu ekubekeni nasekubambeni izinto.

10. Lo matshini uxhotyiswe ngenkqubo yokupholisa ye-aerosol yokugrumba nokupholisa izinto.

11. Umqadi we-gantry yomatshini uxhotyiswe ngesigqubuthelo sokukhusela esifana ne-organ, kwaye umqolo webhedi uxhotyiswe ngesigqubuthelo sokukhusela esifana nepleyiti yentsimbi ye-telescopic.

12. Umatshini usebenzisa inkqubo yolawulo lwamanani ye-Siemens 840D SL, enokwenza ucwangciso lwe-CAD oluzenzekelayo kwaye inomsebenzi wokuqaphela umaleko. Inkqubo inokumisela ngokuzenzekelayo umgama wokusebenza ngokobude besixhobo (ukufakwa ngesandla) kunye nokuphakama kwesakhelo, ngokubanzi yi-5mm, kwaye ixabiso layo linokubekwa ngokweemfuno.

13. Umatshini uxhotyiswe ngenkqubo yokuskena yebha ethe tye (ikhowudi yebha enemilinganiselo enye, umgangatho wokubhala ikhowudi weCODE-128), ebiza ngokuzenzekelayo inkqubo yokucubungula ngokuskena ikhowudi yebha ethe tye yesakhelo ngesikena esiphathwayo esingenazingcingo.

14. Lo matshini unomsebenzi wokubala wokuqokelela ngokuzenzekelayo inani lemingxuma yokugrumba kunye nenani lezinto ezicutshungulweyo, kwaye awunakususwa; ukongeza, unomsebenzi wokubala imveliso, onokurekhoda inani lezinto ezicutshungulweyo yinkqubo nganye yokucubungula, kwaye unokubuzwa kwaye ususwe.

Uluhlu lwezinto eziphambili ezithunyelwe ngaphandle

| HAYI. | Into | uphawu | Imvelaphi |

| 1 | Izikhokelo eziLula | I-HIWIN/PMI | ITaiwan, iTshayina |

| 2 | I-spindle echanekileyo | UKenturn | ITaiwan, iTshayina |

| 3 | Inkqubo yokuskena ibhakhowudi ethe tyaba | ISIMBO | IMelika |

| 4 | Inkqubo ye-CNC | I-Siemens 840D SL | Jemani |

| 5 | Injini yeServo | I-Siemens | Jemani |

| 6 | Injini ye-servo ye-Spindle | I-Siemens | Jemani |

| 7 | Iindawo eziphambili ze-hydraulic | I-ATOS | ElamaTaliyane |

| 8 | Itsheyini yokurhuqa | IsiMisumi | Jemani |

| 9 | Izixhobo zombane eziphantsi kwamandla ombane | USchneider | Fransi |

| 10 | Amandla | I-Siemens | Jemani |

Umsebenzi wethu kukukhonza abasebenzisi bethu kunye nabathengi ngezinto zedijithali ezisemgangathweni ophezulu nezinoburhalarhume kuMenzi waseTshayina. Umatshini wokubhola weSF8 FINCM Double Spindle womatshini wokubhola isakhelo selori, Ngoku sinezisombululo ezine eziphambili. Iimpahla zethu zithengiswa kakhulu kungekuphela nje kwicandelo laseTshayina, kodwa zamkelwe nakwiimarike zamazwe ngamazwe.

Umenzi weUmatshini wokugrumba isakhelo selori saseTshayina, Umatshini wokubhola, Zonke iimashini ezingenisiweyo zilawula ngokufanelekileyo kwaye ziqinisekisa ukuchaneka komatshini kwiimveliso. Ngaphandle koko, sineqela labasebenzi kunye neengcali zolawulo oluphezulu, abenza iimveliso ezikumgangatho ophezulu kwaye banakho ukuphuhlisa iimveliso ezintsha ukwandisa imakethi yethu ekhaya nakwamanye amazwe. Silindele ngokunyanisekileyo ukuba abathengi beze kwishishini eliqhakazileyo kuthi sobabini.

Iprofayili emfutshane yeNkampani  Ulwazi lweFektri

Ulwazi lweFektri  Umthamo woNyaka weMveliso

Umthamo woNyaka weMveliso  Amandla okuRhweba

Amandla okuRhweba